[This review originally appeared on the Deactivated Guns Collector’s Association website in May 2002 – Ed.]

And finally I get around to reviewing the SIG-Sauer P226! This review is going to have more detail than the others, I warn you in advance, because I know a lot about this gun, much of which is not written down in books; so prepare to receive an education!

The P226 is a double-action semi-automatic pistol, originally chambered for the ubiquitous 9mm Parabellum (otherwise known as 9mm Luger and 9x19mm NATO), although in the past few years it has also been chambered for .40 S&W and .357 SIG.

The gun was conceived for the US JSSAP pistol trials in the early 1980s, the winner of which would be the new sidearm for the US armed forces. In the event, Beretta won with the 92F, but the P226 was the only other pistol in the original XM9 trial to be considered a “technically acceptable” finalist. Beretta won because they had a plant in Maryland able to immediately tool up and make the pistols (important because the plant was on US home soil) and also because they tendered a lower price for technical support, although my understanding is that the tender for the P226 pistols was actually lower. (I have to say I think the Beretta was the better choice because it had been in production since 1975 and was a more fully developed design at the time than the P226).

The first prototypes of the P226 were made in 1980, and the initial guns were little more than the earlier P220 pistol adapted to use a double-column magazine, indeed ironically I understand one of the prototypes used the Beretta 92 magazine!

Back then, SIG-Sauer did not have a US importer, and so they entered into a deal with Saco Defense, Inc. of Maine to supply the pistols used in the US military testing. And now we get into the bit where I know more than most other people.

These guns were supplied in a red pistol rug with “SACO DEFENSE, INC.” and “XM9/226” in gold lettering printed on them. The guns came with two magazines. They were also substantially different in design from later guns. The frame for example had completely straight rails – guns after that had frame rails that were simply bulked up and from U130000 or so to U180000 and something, scallop cuts were put in the rails to relieve stress. This was done because it was found during testing that the frame rails on the XM9 test guns cracked, and even after the redesigns they continued cracking until the metallurgy was improved around U150000.

Contrary to what it says in the book: Das grosse Buch der SIG-Pistolen, the standard reference work, the guns had matte black sights, not contrast sights. Another thing which sets them apart are the serial numbers, the serial numbers are stamped in italics on the frame, and the serial numbers, U85941 through U85980, are the only P226 serial numbers under U100001. Several of the guns were destroyed in testing when the frame cracked, I know for certain at least three of them were wrecked during various tests. After the trials were over, the guns were returned to Saco, and from there many of them found their way into the hands of employees. I think some were also returned to Germany for evaluation and a few were sold off from there also.

If you ever find one, don’t have it deactivated, as they are worth a mint and easily qualify for section 7(3) status due to their rarity and prototype status. The one I shot gave groups ten inches high at 25 yards, so I wouldn’t bother getting one as a shooter even though all of them have wear on them, so you don’t do much damage to the value by shooting it.

After the political fallout from the choice of the Beretta, this led to the XM10 pistol trials, and once again the P226 was a contender, the serial numbers run from U104006 through U104055 for these pistols. Eduard Kettner had a few some years back and they also qualify for section 7(3) status. There’s nothing particularly special about them other than the serial numbers.

Okay, now we’re past the juicy bit back to the review:

I’ve already covered the basics of how the SIG-Sauers work in the P225 review, so I won’t rehash it here, if you want the nitty gritty, I suggest you click here. Suffice to say the P220-series pistols are very clever designs, especially the pinned-in breechblock and the method of locking the barrel into the slide, and there are a number of patents on the gun, which when they expired were happily copied by many others, notably Glock.

The P226 is probably the best of the P220-series guns for target shooting for various reasons (with the possible exception of the .45 version of the P220), and although it has never been officially adopted by any Army that I’m aware of as the standard sidearm, it is widely used by specialist units including our own 22 SAS, not to mention many other British Army units and also the US Navy SEAL teams (in British service it is known as the L105A1 self-loading pistol). It is also widely used by police, particularly in the US. Total production of the P226 in all its variations is approaching 600,000, which is a lot but the Beretta 92FS and equivalent Glock models are in the millions!

One of the main selling points of course is the increased magazine capacity (over the P220 and P225), the standard magazine holds 15 rounds although a larger magazine that holds 20 rounds is also made:

The magazine pictured at top is a twenty rounder that has been chrome-plated and the bottom magazine has the optional rubber floorplate. The .40 and .357 models come with a 12-round magazine made by Mec-Gar for Sauer, and in the US all models come with ten-round magazines made by Mec-Gar. For the anoraks among you, the early P226s, pre-U150000, came with magazines that had “P226” etched on the bottom of the floorplate. Contrary to what you will read in US gun magazines, Sauer still makes magazines for the P226, it’s only in the US and the .40 and .357 models where the guns come equipped with Mec-Gar mags. Sauer also made one batch of ten-round 9mm magazines in 1994; these are substantially rarer than the Mec-Gar magazines although I wouldn’t go so far as to say that they’re collector items.

One tip; if you take the follower out of a ten-round magazine and put it in a fifteen-round magazine, it increases the capacity of the magazine by one round.

The P226 has one of the best magazine-release catches I’ve come across:

It’s good because you can get your thumb on it without having to move your hand, provided your thumb is long enough. It’s also reversible (with a lot of fiddling) for the left-handed among you.

Note also the design of the trigger; there are four distinct trigger designs. The first was basically identical to the P220 and was used on the XM9 test guns. Production guns were fitted for many years with a grooved trigger, which was replaced around 1993 with a smooth trigger as pictured – a very good design change, it was always one of my complaints. There is also a “short” trigger, which as the name implies shortens the trigger reach, as it is thinner in profile. I have never personally been impressed with the short trigger, because if your trigger finger is that short you will find the edge of the frame will dig into your finger. A better idea is to get a thinner gun, such as the P220.

The barrel of the P226 is a two-piece design, some say this is a bad idea because it might fall apart faster:

I think this is probably true, as I’ve seen a P226 that had a huge number of rounds through it where the barrel had bent slightly upwards where it joins to the chamber, however I have to say this is entirely academic as many other things will have worn out or broken by the time your gun gets to that point (and we’re talking about deactivated guns anyway, where it will never be an issue!) The barrel is not chrome-lined as some articles I’ve read say, by the way.

If you compare the position of the locking block under the barrel with a P220 you will see that some thought went into the P226, as the position of the locking block leads to the barrel being locked with the slide very slightly longer than in a P220, which makes it very slightly more accurate than the P220, at least in the 9mm version. I doubt most shooters will notice the difference however.

The underside of the muzzle of the gun is where a lot of questions get raised by shooters, because of the markings:

The stamp that looks like a bug at the top is the mark for the Kiel proof house (for those of you who don’t know, proving is the firing of proof loads through the gun to ensure it won’t blow up), the mark underneath that (which appears on the barrel and frame also) is the actual proof mark, indicating the gun has passed proof for nitro loads. The two-letter code underneath indicates the year the gun was proved (not necessarily the same year that it was manufactured). The one pictured has a “KH” proof mark – the “K” stands for “9” and the “H” stands for “7”, indicating it was proved in 1997.

Sauer has in the past few years started shipping unassembled guns over to the US, where they are assembled and proved prior to sale. They’ve done this to avoid the costs of proving the guns, so guns sold in the US often don’t have the German proof marks. SIG Arms in the US do their own proof test and the barrel is marked with a “P” in a circle. They can do this because the US is not a signatory to the CIP proving treaty (as are most European countries and several others besides).

Note also the braided recoil spring in that photo, a carry over from the P225, I’ve never been sure that it’s strictly necessary on the P226 but it’s just one of those Teutonic engineering things.

The breech block is one of the cleverer features of the P226:

When P226 slides are made, they start off as a piece of sheet steel that is shaped over a mandrel, and then the breech block is pinned in. This was done to save costs originally, however the march of technology has taken over and it is in fact cheaper now to make the slide from a block of steel using CNC machines. However I prefer the old method because it makes maintenance easier and the gun balances better as the sheet steel slide is lighter.

One question I hear asked a lot is whether this is a weak spot, and I have heard various horror stories (mostly rumours, I suspect). All I can say is that it passed US military testing, and that has got to be the toughest in the world. I have had one breech block pin crack at the gap between the block and the slide, this can be detected easily as the breech block rattles in the slide. However the gun kept functioning, although accuracy did suffer (which is how I noticed it!) I also have seen a breech block that cracked around the pin and fell out of the slide, but that has to be extremely rare. Anyway, fear not, because in 1996 they redesigned the breech block and made it stronger where the pin goes through it, so I would say it is highly unlikely you will have a problem with a newer gun.

In 1996 SIG-Sauer also started selling P226s with slides machined from stainless steel bar stock, these slides are much stronger but they also have more mass so the gun feels top heavy. I personally don’t like them, unless you also get a P226 that has a stainless steel frame (either the P226 SL or one of the Sport II SL models). The new slide design was necessary to allow the P226 to be chambered for the more powerful .40 S&W and .357 SIG cartridges, as the slide velocity is tamed by the increased mass of the slide.

I have to say quite honestly I’m not a big fan of the P226 in .40 or .357, SIG Arms made it because the Texas Dept. of Public Safety wanted it, but it has the same magazine capacity as the smaller (but wider) P229, and I personally think the P229 makes more sense. I had one of the first .357 SIG P226s and it was not put together well. The sights were way off the point of impact of the bullet, and worse than that the tolerances of the slide were out of whack. The slide is made in the US while the frame is made in Germany, and it was obvious they hadn’t got their sums right when fitting them together. The end result was a slide that was too tight to fit the frame, and in short order most of the finish on the frame rails was removed. This wasn’t an isolated case either, other people I knew who bought guns from the same batch had it happen too. I assume by now they’ve fixed this problem but my advice if you’re buying one to shoot rather than as a collector’s item is to get the P229.

There’s another problem with this version of the gun too, but it leads into another subject so I’ll deal with them together:

The Achilles’ Heel of the P226 (and the P220-series in general) is the trigger bar spring:

In the picture it’s that piece of wire that goes from behind the magazine release to the trigger bar.

Sauer have fiddled with this thing so much that it’s a wonder the pistol grip makers of the world haven’t sued them. The first problem is that as you can see in the picture, it “eats” through the frame as it rotates in the hole when you pull the trigger. I have a well-used P226 where it has actually eaten its way well into the magazine release button backplate.

The second problem with this spring is that it breaks a lot. Sauer started making it out of a tougher metal around 1993, but this just made the problem of it eating through the frame worse.

Eventually, in 1998, they redesigned the spring completely, and now it looks like this:

It doesn’t break anymore, and it doesn’t eat through the frame as quickly, but you can’t use your old grips with it. So Sauer redesigned the grips. To begin with, they looked like the ones pictured here:

These grips were great, and worked fine. (There are actually minor differences between the grips used on the older pre-U150000 or so guns and the ones after that, but they look and feel the same). However, in 1996 they went to these grips:

Which are, quite frankly, awful. They’re intended to look like the grips on the P228, but the stippling is nowhere near as deep, and they do not give a good solid grip on the gun as they are too slippery. This was especially a problem with the greater recoil of the .40 and .357 versions of the gun, and you couldn’t put a set of the old grips on because they wouldn’t fit over the new trigger bar spring!

Eventually someone appears to have figured out that they made a mistake, and a couple of years ago they redesigned the grips and gave them deeper stippling and now you can actually get a grip on the gun. (As far as I know all the P226s with the new laser-engraved serial number have the latest grips). However, my suggestion if you are a target shooter is to ditch them and get a set of Nill grips:

I find it slightly amusing that in their own brochure, Nill grips complain about the fact that Sauer is constantly redesigning the gun and they have to redesign their grips as a result! Sauer actually uses Nill grips or Hogue grips on the Sport models of the P226.

Different models

Sauer has made a number of different models of the P226 over the years, I am going to try and list all the ones I’m aware of here. In the US many of the models have different names if they were ever imported into the US, so if that’s where you are this list will be of limited use to you.

By far the most common model is the standard P226 as pictured at the top of this page, the earlier guns (pre-U150000 or thereabouts) can be identified by the profile of the slide, the rear of the slide at the top of the serrations is angled at about forty-five degrees on the earlier guns. Excluding the XM9 and XM10 test models, that was it until the late 1980s when Sauer started making a nickel-plated model. This comes in two flavours, one with all the steel parts finished with nickel-plating and another model where the frame is also nickel-plated. The version with the nickel-plated frame is mildly collectable as it is the only version of the gun that has ever come from the factory with a different finish on the frame. It was made from about 1988 to 1991, but there were concerns about the strength of the frame (it is rumoured), so in 1992 it was replaced with the version with just the steel parts finished in nickel.

There is also the K-Kote version, another finish that is basically a baked on resin that provided superior rust protection to the standard phosphate finish. One of the problems with the P220-series guns has always been that they rust more easily than the competition, hence the K-Kote finish. According to the SIG Arms brochure this finish is still available, but I haven’t seen a new P226 with this finish for ages.

In 1985, Sauer made a commemorative version of the P226 to celebrate the 125th anniversary of SIG. called the JP226. This comes in a display case, with various gold-plated parts, a blued slide, gold lettering on the slide and carved wood grips with a scroll pattern on them. This is obviously a collector’s item, although they’re not worth as much as some people seem to think. There is another model made for collectors that came out in 2001 called called the P226 SL Jubilee, to celebrate the anniversary of the founding of Sauer & Sohn. Only 25 of these have been made, and they’ll probably be more collectable than the JP226 (because 3,000 of those were made). The gun has a high polish on the flats of the slide, engraving, gold plated small parts and Nill grips.

In 1994, things got more interesting when Sauer started making a target-shooting model of the P226 called the P226 Sport. All the ones I’ve examined have a 1994 proof mark on them, and they were only available from the factory from 1994 to 1996. And this is what it looks like, except they came with Nill grips:

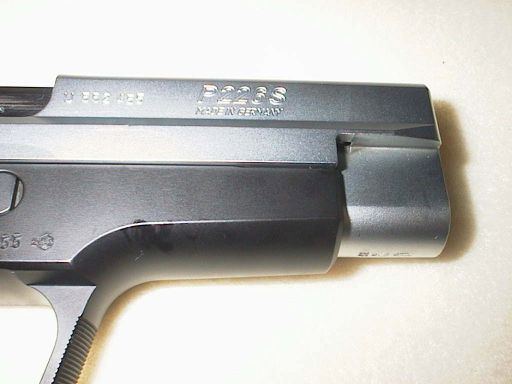

Note the chrome finish, and the LPA adjustable sights that are mounted in a recess in the slide. It has a nice trigger pull too! The markings are quite interesting:

Note the “S” on the end of “P226”. This model was never imported into the US. People sometimes get confused between this model and another model called the “Classic Sport”, this was made for a German distributor, but it’s not as exotic, it’s simply a P226 with LPA sights, a trigger job and Hogue grips.

Around this time (maybe a bit earlier) Sauer also started making a double-action only version of the P226, mainly because of a contract from the NYPD. However, rusting problems caused the withdrawal of the P226 DAO from the approved list of guns, although it has recently been put back on the list with a new version with nearly all the parts other than the frame nickel-plated together with a stainless steel slide, to prevent the rusting problem.

In 1996 the number of P226 models began to multiply like rabbits, and frankly I have a hard time keeping track of them all. In 1996 the introduction of the stainless steel slide led to new models of the gun with the slide in 9mm, .40 S&W and .357 SIG, and those models are also available with a nickel finish on the steel parts. Originally the slide was finished with a phosphate finish, but currently they are finished with something called “Nitron”, which I think is basically a phosphate finish mixed with something to make it stick to stainless steel better – I’m not sure to be honest, the sales literature is a bit vague.

In 1998 Sauer decided to build on the success of the P229 Sport and P220 Sport models and came out with a new Sport model of the P226, a very different beast from the gun pictured above, called the P226 Sport II, this is essentially the P226 with a stainless steel slide, a bull stainless steel barrel and was available in two barrel lengths, 112mm (flush with the end of the slide) and 126mm, although this model was discontinued in 1999 and it now comes with a 139mm barrel.

In 1999 Sauer really outdid themselves with the P226 Sport II SL – I have done a separate review of this gun that you can read by clicking here. This gun was the first P226 model with a stainless steel frame. It also is fitted with extended controls. It is marred by the barrel weight, which is totally unnecessary in my opinion, and Sauer have now recognised this by introducing a model with no barrel weight and a standard length 112mm barrel. My personal view is that this is the best P226 model, especially for target shooting. Recently (2002), Sauer have also started making both of these guns (with and without barrel weight) with Aristocrat sights for PPC/1500 events. On the 139mm barrel length model with the weight the front sight has been moved from the slide onto the barrel weight – which means you can’t use it without the weight. Maybe you 1500 shooters can cope with it, I don’t know, but it’s not my cup of tea.

In 2001 Sauer also came out with a model called the P226 SL, this is essentially the standard P226 with a stainless steel slide and frame, although it has the standard carbon steel barrel. This is not to be confused with the earlier P226 SL, a name Sauer applied to the P226 with stainless steel slide only when it first came out.

The current P226 SL is available with a bare stainless steel finish or with a coating of Ilaflon, the same stuff that your frying pan is probably coated with! Sauer have been heavily promoting this model for use in production class IPSC, although I suspect it will sell better in the US for law enforcement purposes.

At the time of writing there is no version of the P226 SL or the Sport models in any calibre other than 9mm, this is because they are largely intended for target shooting sports in Europe. I suspect the P226 SL will be made in other calibres eventually though.

And for the sake of completeness, I should mention the P226 is available with Trijicon SIG-Lite night sights, which are worth getting even if you don’t intend to use your gun in low light as they give a better sight picture than the standard sights, pictured here:

Also I think I should mention the boxes, up until about 1991 they came in a yellow cardboard box, and after that a grey cardboard box, until 2001 when they started selling them in plastic carry case boxes. In the US the packaging has been different since about 1992 from Europe, there has been a succession of plastic boxes, some with padlocks (and the US guns come with a much crappier manual than the European guns, with their Swiss four-language manual). The carry case pictured at the top is a SIG carry case, that is an optional accessory. If the gun was proved in Germany it also comes with a test target, I think SIG Arms has started supplying test targets with guns assembled there recently, shot at the plant in Exeter, New Hampshire.

So…

By now you can tell that the P226 is one of my favourite pistol models, they aren’t as durable as a Glock or an H&K USP, but they are more accurate than most of the competition, have a better trigger pull and are extremely reliable. They also fit my hand better than nearly anything else! From a collector’s standpoint, the P226 is a classic design and one of the most significant of the past twenty years, if you’re trying to think of a reason to spend all that money.

If you want one, you shouldn’t have too much difficulty finding one, even here in the dire depths of Britain, although obviously it will have to be deactivated. They aren’t inexpensive though, although occasionally you will find one at an arms fair or in Gun Mart at a more reasonable price than a new one. Your local section 5 RFD can order one for you from the UK importer, Beechwood Equipment (who don’t sell deactivated guns, by the way, your local dealer will have to get that done for you), and there are a fair number of grey imports knocking around too.

If you’re examining one, you can tell how worn it is (if it’s the sheet steel slide model) by dropping the magazine, cocking the hammer, and waggling the rear of the slide. If it waggles a lot, it is well-worn.

There is more information on the Sauer website, and also the SIG Sauer US website, although I warn you in advance that website will confuse you as many of the models have different names in the US.

Have fun!